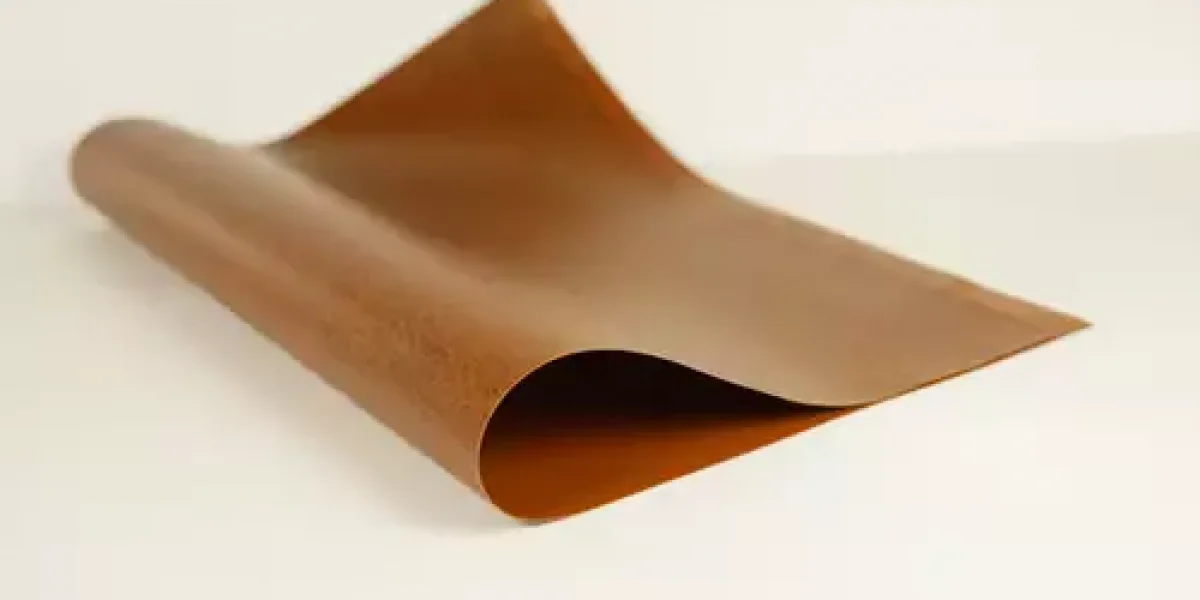

Generally, PVC leather, also called artificial leather, refers to the leather mainly made with PVC resin. PVC leather stands for polyvinyl chloride. From the point of chemical, it is manufactured by replacing the hydrogen group with a chloride in the vinyl group. Then this replacement is used for the combination with other chemical to create a long-lasting plastic fabric with excellent performance like easy-cleaning and maintenance-friendly. From the point of manufacturing technique, PVC leather is made of a non-woven fabric coated with the mixture of PVC resin, plasticizer, stabilizer, and other additives. The finished PVC leather has high strength with low manufacturing cost, widely used for various bags, seat covers, clothes, etc.

Unique Features of PVC Leather

Excellent Properties

Being made from PVC resins, PVC leather has outstanding waterproof and rainproof performance. What’s more, it can withstand certain high temperature and resist fire and static electricity, which makes it ideal for outdoor products. In particular, it is easy to process PVC leather so its price is more inexpensive compared to other kinds of artificial leather.

Safe & Durable

The PVC film on the PVC leather is pressed a high temperature of 110 degrees by a special vacuum laminator, so it is not easy to fall off. Some people may say that PVC leather is a chemical product with certain toxicity and odor, which can does harm to the environment. However, as a matter of fact, the materials for the production of PVC film are specially refined, and the toxic substances are completely extracted. Thus, PVC leather is 100% non-toxic and free of odor, causing no irritation to human skin or respiratory system. For people with paint allergies, furniture or kitchenware wrapped in PVC leather is quite suitable.

Easy to Clean & Maintain

PVC leather is easy-cleaning and maintenance-friendly as a kind of artificial leather. It has great stain resistance and its non-porous surface can prevent dirt and spills from penetrating into the leather. For daily clean-up, wiping with wet cloth and clean water is well enough.

Production Methods for PVC Leather

Coating Technique

The PVC plastisol is directly coated on the pretreated fabric substrate with a squeegee or roller, and then through a series of processes including plasticized, embossed, cooled, and coiled to form PVC artificial leather.

Features

1. It has high requirements on the strength and density of the base fabric like general knitted fabrics, which are not applicable.

2. It needs a lot of emulsion resin, and it is not easy to control the quality of the product, so it is only suitable for the production of thin leather.

Lamination Technique

First, the sheet is made by rolling, and the adhesive is pre-coated onto the fabric substrate, then the treated fabric substrate and sheet are bonded together simultaneously by an embossing lamination device. There are two methods of lamination: applying the adhesive to the PVC sheet and then attaching the base, or bonding the prefabricated sheet to the fabric substrate after heating, based on the hot melt properties of the thermoplastic.

Features

1. Have great flexibility, and is suitable for producing small batches and multiple varieties of products.

2. It can produce products with three-layer structure, suitable for the thicker products, such as floor leather, conveyor belts, etc.

WhyChooseCAIWING?

We are a professional artificial leather manufacturer and supplier, providing high-quality faux leather, PU leather, PVC leather, widely used for various industries like clothing, furniture, boat, etc. If you are looking for upholstering solutions for your projects, welcome to contact us at